Hwang Hyungshin makes furniture with polypropylene (PP) board, which is normally used as a material for moving boxes. If you heat up these boards after arranging them into a pile, the boards stick to each other as their surfaces melt. When they cool they become solid like stone, which is then used as a material in the Layered series products, including stools, tables and shelves. The structural forms and monotone colours of these products make it difficult to assume that they are made of plastic. However, if you take a closer look, you can clearly see the holes of plastic cardboard on the surface. Hwang is persisting with varied experiments in his recent work, which shows changes to choice of materials while also keeping the original form or applying one technique to different materials.

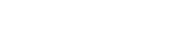

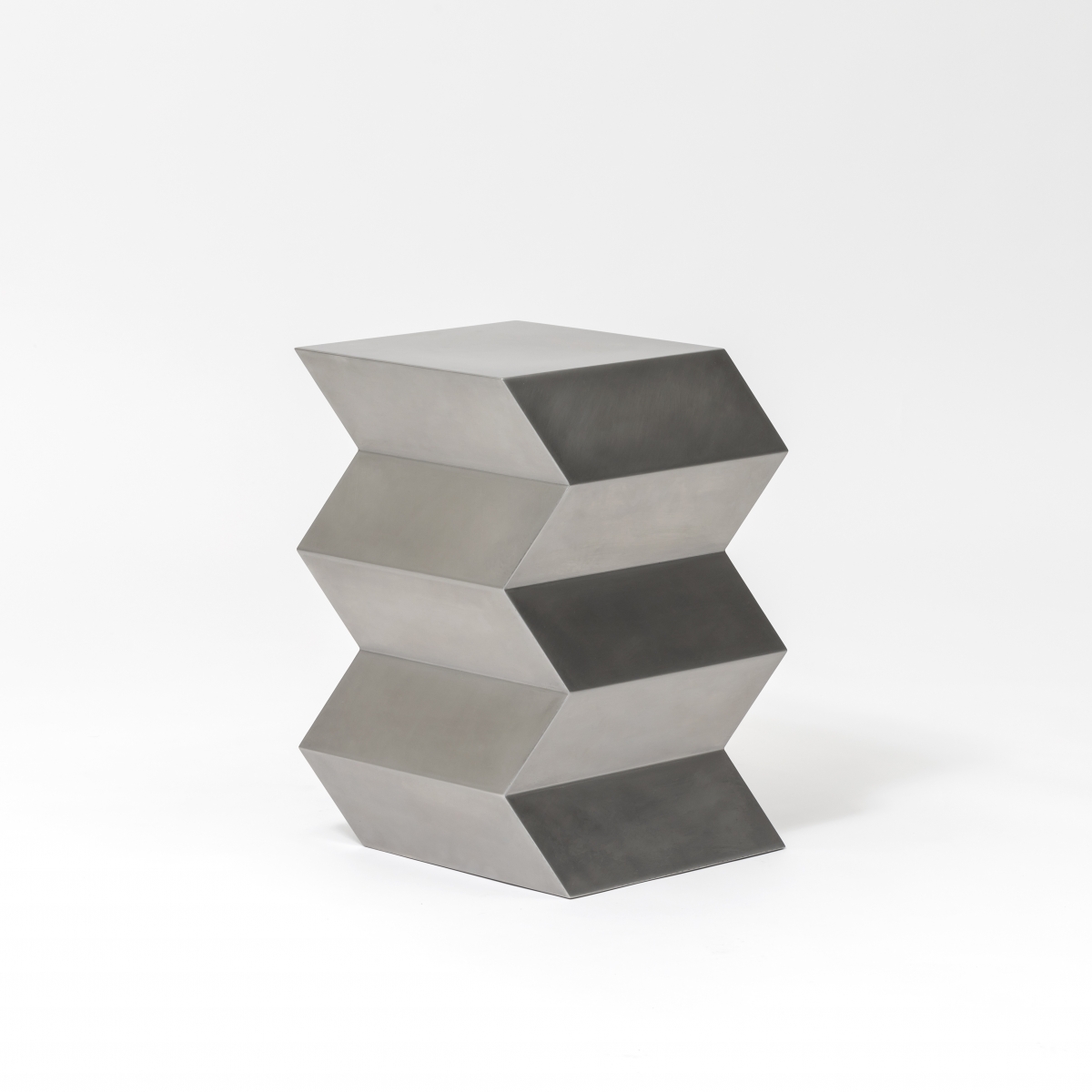

Hwang Hyungshin, Zinc chair 01 (Layered steel),

Stainless steel, 300×600×1100mm, 2018 (©Cho Neulhae)

Interview Hwang Hyungshin × Choi Eunhwa

Choi Eunhwa (Choi): Your early works are characterised by the use of diverse materials, including brick, concrete and plastic. Considering that you studied woodworking and furniture, it surely would have been easier for you to work with wood.

Hwang Hyungshin (Hwang): As an undergraduate, I was not good at woodworking (laughs). I learned how to use tools in my first year. Then in the second year, I took a stool making class, and there I had to work with wood. To produce quality work, you must have a good understanding of the material and you must be skilled in using your tools. In my case, the pressure to produce so many works in a short period of time was too high at that point in my career. After all, I grew tired of wood so began to turn to other materials. I picked up bricks at a reconstruction site, made a mixture of concrete with other materials, and experimented with powdered plastic. The funny thing is that I ended up returning to wood in graduate school. Now I’m not fussy about material, but I continue to be open to working with various materials.

Choi: Your use of PP board is also interesting, particularly as it is seldom used in furniture design. How did the Layered series begin?

Hwang: The first product in the series was an armchair that I made when I was an undergraduate. I made the chair by layering white cardboard. After finishing the work, I didn’t use this technique again for a long time. A few years later, I was commissioned to make a revolving door. I picked cardboard again. However, paper cardboard is not durable enough, so I chose PP board, a plastic cardboard, as substitute. If you look closely at the section of a cardboard, you can see the top and bottom are covered with a membrane, and between them, there are gaps running in zigzag formation. Therefore, if you adjust your eye-level properly, you can see through the cardboard. Likewise, as for the revolving door, there exists a door, but you can still see the scenery behind it. Depending on the eye-level, movement or position of a viewer, the image of the other side comes in or out of sight. After that project, I let this technique lie idle again for a couple of years. Later, I developed it further for my graduation project in graduate school, and since then I have been continuing to work on it.

Choi: Hearing you makes me understand that the Layered series is an evolving project. Have there been fundamental changes in your work when you look back to the work of your early years?

Hwang: At first, I was inept in heat and shape control. I often ended up producing a crumpled shape which was not what I intended, and the details were not often satisfactory either. I went through a lengthy process of trial and error because there were so many things to decide, such as how much material to use in creating a planned form, whether to heat a particular element, or which manufacturing process to proceed with first. Now I carry out the whole working process in a skilled way, using a custom-made heating device. My work efficiency has much improved too. In the early days, it took so much time to pile up horizontal layers one-by-one without any visible tricks, but now I have adopted a new working system by which I make block units beforehand and then simply assemble them to construct a product.

Choi: What advantages of PP have you discovered?

Hwang: I take great inspiration from architecture and the city. I’m very interested in monotone colours, geometric building forms and the shades created by the undulating outlines of a building. I think the Layered series products, in which black PP boards are layered, resemble a multi-story building. The blow holes that are strewn across the surfaces of the furniture create a building façade seemingly of closely spaced windows.

Choi: It seems you have great affection for architecture.

Hwang: I’m a big fan of Peter Zumthor and Mario Botta. I learn many things from them, such as various philosophies of architecture, different ways of using materials, or new attitudes to working with a longer view. During my summer holidays this year I traveled to Switzerland. It was simply an architectural tour, and so I visited Therme Vals by Zumthor, and was completely fascinated by how he has neatly piled up local stones. I associated it with my work and felt real personal excitement. Botta’s Church San Giovanni Battista was also impressive. One of my bucket list items was to see this church with my own eyes, and visiting it in real life was mind-blowing. I thought to myself I don’t ever need to see anything else.

Choi: In your solo exhibition ‘Layered-Steel’, held at g.gallery, you presented new works in the Layered series, for which you used metal while keeping the layering technique.

Hwang: I changed the material to stainless steel while keeping the sculptural quality of furniture by layering PP. Naturally, the structure had to be changed as well. I added a new internal structure system to support the load. It also became possible to create the same forms without layering the material, so the working method became easier.

Choi: The recent Keft series looks interesting too. It seems that the two intersecting structural members can be joined only when they have an exact size and curvature. How did you make it?

Hwang: When making a curve for a Layered series product, I make a cut on only one side of a PP board and bend it along the cut line. I thought it might be possible to apply the same technique to wood, so I started experimenting with what resulted in the Keft series. A specific technique called ‘Keft bending’, which makes gaps with a certain depth at regular intervals to create a curve, is applied during the stool making process. You can see the stitch-like pattern lining the edge of structural members, it is cutmarks produced by a Computerized Numerical Control (CNC) machine.

Choi: When judging by images only, all of your works seem to be based on different ideas, but they are of course associated with one another. I wonder what kind of work will come next.

Hwang: I don’t have any grandiose plans. I will probably look into something that I couldn’t discover or that I missed in my previous projects. There can be some changes in details, yet they wouldn’t go far beyond the bounds of what I have explored so far. I replaced paper cardboard with plastic cardboard, and experimented with new proportions. They would be that sort of thing. I want to develop my own style gradually, by continually revisiting and reflecting on my memories.

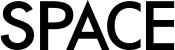

Hwang Hyungshin, Stool 01 (Layered steel),

Stainless steel, 300×300×450mm, 2018 (©Cho Neulhae)

Hwang Hyungshin, Console 02 (Kerf series),

Birch plywood, 900×300×900mm, 2016 (©Ji Yohan)

Hwang Hyungshin, Stool 04 (Kerf series),

Birch plywood, Various size, 2016 (©Cho Neulhae)

hyungshinhwang.com