SPACE July 2025 (No. 692)

I AM AN ARCHITECT

‘I am an Architect’ was planned to meet young architects who seek their own architecture in a variety of materials and methods. What do they like, explore, and worry about? SPACE is going to discover individual characteristics of them rather than group them into a single category. The relay interview continues when the architect who participated in the conversation calls another architect in the next turn.

OhLee house (2020) ©Woo Jihyo

Interview Kim Dohyeong, Son Juhui co-principals, SONKIM Architects × Kim Hyerin

Wooden Structures as the Natural Choice

Kim Hyerin: Both of you graduated from the same university with a degree in architecture. After graduation, Kim Dohyeong gained practical experience working as a carpenter and construction site manager, while Son Juhui worked at an architectural firm specialising in wooden structures. Perhaps that’s why SONKIM Architects is known for its wooden structure-based projects.

Son Juhui: I was actually a year ahead of Kim Dohyeong in university, and we were a campus couple. (laugh) Both of us studied under professor Tomii Masanori, who focused primarily on wooden structures. He placed great significance on hands-on experience, often calling for students to participate in community-building projects. We learned a variety of construction methods such as construction methods using traditional wooden structures and pre-fabricated wood construction on-site.

Kim Dohyeong: There wasn’t a formal curriculum for wooden structures at our university. However, it was the first structural system about which we developed a deep understanding, so it felt natural to become so familiar with it. In the beginning, you rarely get large-scale commissions. As a small-scale office, we mostly took on renovation projects with limited budgets which naturally led us to work with smaller, more delicate materials. Many of our projects aren’t well-suited for construction methods that require established industrial infrastructure, like concrete or steel frame systems. For instance, when a site is located along a narrow backstreet in a tightly packed neighbourhood, bringing in a concrete pump truck isn’t always feasible. Wooden structures, on the other hand, operate on a human scale. You can carry each piece by hand. In that sense, working with wood felt both natural and necessary.

Son Juhui: We’re based in Jung-gu, Incheon, one of the oldest districts in the city. During the port-opening era, Japanese and Chinese communities settled here. As a result, there are many old wooden buildings from that period. The area is designated as a historic district, and it’s filled with small, aging structures. Most of the commissions we received were renovation projects, and many of the buildings involved were either partially or entirely built with wood. Even so, we’re not limited to wooden structures. We’re always open to working in other projects. (laugh)

Kim Hyerin: While you’re not exclusively focused on wooden structures, you certainly have more experience working with them. What are your thoughts about the recent shifts in the design and implementation of wooden structures?

Kim Dohyeong: These days, wooden structures have been incorporated into the industrial system and are becoming increasingly quantified. There have been technical advancements in areas such as the improvement of fire resistance, the management of internal moisture permeability, and securing airtightness. In the past, even structural engineering firms had limited understanding of wooden structures. They saw wood as a material that did not have the capacity for standardisation. However, in countries more advanced in wooden structures, standardisation efforts have been made, and those technologies are gradually being adapted here in Korea as well. On-site, even carpenters are now more inclined to follow detailed instructions compared to the past. What once used to rely on sensory apprehension and experience is now transitioning to a more regulated and measurable practice.

Son Juhui: With the use of pre-fabricated wood constructions, there are now cases where carpenters are hardly needed on site, aside from the final finishing stage—even for wooden structure-based projects. From a technical perspective, wood is weaker than steel or concrete, so special structural strategies are required when applying large-span structures. There are relatively simple methods such as increasing the cross-sectional dimensions or using simple truss forms. However, more advanced techniques such as hybrid wooden structures combining wood with metal and small wood elements, non-conventional wooden structure, and CLT-based structure, are employed internationally nowadays.

Kim Hyerin: Kim Dohyeong, you trod quite a unique path after graduating from university, beginning your career as a carpenter.

Kim Dohyeong: Back in 2013, professor Tomii led the renovation of the Incheon Gwandong Gallery. It was a project that involved reinforcing the structure with wood, and it was carried out by a traditional Korean carpenter. I worked on-site, almost like a construction manager, closely following the carpenter throughout the project. That experience led me to join a light-frame wooden structure team later on. Altogether, I spent about three years on the site.

Son Juhui (left) and Kim Dohyeong (right)

Office of SONKIM Architects

Office of SONKIM Architects

Patchworked Space

Kim Hyerin: SONKIM Architects is known for pursuing architecture that minimises the amount of waste. What led you to focus on sustainability?

Son Juhui: Every material we use has gone through a long and complex process. Simply consuming and discarding materials never sits right with us. Since we’re involved in every stage of the process, from design to construction, we try to take responsibility and put those values into practice wherever we can. To be honest, there are many times on-site when we can’t follow through due to practical constraints.

Kim Dohyeong: I’m more driven by practical concerns. Most of our projects are small in scale, and our clients are everyday people. We’ve sometimes used leftover materials from other sites due to tight budgets. I think this makes our work a bit different from what many other firms are doing. (laugh) Reusing materials from previous exhibitions helps cut costs when there’s little budget but too many ideas. We also try to design in ways that allow clients to participate directly, reducing labour costs.

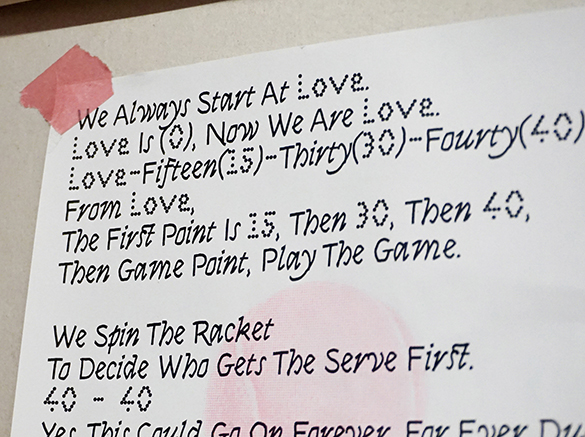

Kim Hyerin: The plywood used for the ceiling finish and furniture in OhLee house (2020) material repurposed from Incheon Art Platform’s exhibition. I’ve noticed that during the exhibition, you intentionally avoided using adhesives and minimised nail marks by using thin pins, with reuse in mind from the outset.

Kim Dohyeong: Most exhibition projects are driven by speed—built and demolished quickly. Whenever I work on exhibition projects, I try to approach it with reuse in mind. I choose methods that minimise entropy as much as possible. These days, many people want to reuse materials from a sustainable perspective, but I also understand how challenging it can be from an operational perspective. Reuse often requires additional labour costs, not to mention time and effort.

Son Juhui: Whenver we receive a commission; we try to use as little material as possible. For instance, if a screen is needed for an exhibition, instead of building a wall and painting it, we create a surface using steel and fabric, since that’s all that is required for the projection. We also use materials that can be rented and returned, or temporary construction materials when appropriate. Even when working with wood, we cut it into standardised sizes with reuse in mind.

Kim Hyerin: Do you also consider sustainability when working on architectural projects?

Son Juhui: When we design, it’s not just about aesthetics. We consider whether each column or beam is truly necessary, how it will function, and how many are actually needed. We’re also very deliberate when ordering materials.

Kim Hyerin: What do you consider when designing form?

Son Juhui: Rather than casually sketching geometric forms of a building I want to create, I spend a lot of time standing in the observer’s point of view. I observe the surroundings and gather clients’ words and how they live. In renovation projects, I pay close attention to how sunlight enters space or how the house has been used so far. I connect all those observations to my design.

Kim Dohyeong: I don’t really have a specific form I want to design. The way I approach architecture is similar to how a surgeon works on the operating table. It is important to notice the needs and challenges, and consider how best to to fix them. Design is more like the final stitch at the end. It’s less about projecting a vision and more about making the most appropriate decisions for the situation at hand.

Kim Hyerin: Are there any projects that reflect this approach to architecture?

Kim Dohyeong: There are several, but to share an example that hasn’t been acted upon yet, the client from OhLee house was recently back in touch. They’re hoping to move to the countryside but mentioned that they’re working with a very limited budget. From that point of contact on, I start to reach out to people I know, asking them not to throw away clean, reusable materials. That whole process feels like part of a continuous flow. I also handle construction, I can manage materials on-site and set them aside. Then, we can piece it together like patchwork. Of course, it would be difficult to do every project this way. But, after building projects, we can carefully sort leftover materials and offer them as a meaningful alternative to clients who aren’t necessarily seeking conventional aesthetics.

PWD(2025)

Within Local Context

Kim Hyerin: Was there a particular reason you chose to base your practice in Incheon?

Kim Dohyeong: It wasn’t something we planned from the beginning. I had lived in Incheon since middle school, but to be honest, the rents were the lowest here. (laugh) We even built our home nearby, which naturally led to taking on more projects in Incheon.

Son Juhui: Also, since we handle construction ourselves and even make furniture, we manage the entire process, from drawing furniture layouts to ordering plywood. Incheon has a lot of factories and suppliers that import plywood, and many of the site managers we work with also live in Incheon. There is convenience in being so closely connected to local industry.

Kim Hyerin: The recent project PWD (2025), a renovation of an old Japanese-style wooden house, is also located nearby. I heard you approached the project with respect for the neighbourhood’s context and the value of the existing structure.

Son Juhui: There are quite a few Japanese-style wooden houses like PWD in Incheon. In the case of PWD, the previous owner had carried out a rather aggressive renovation in the 1970s, cutting through structural columns and disregarding the building’s structural logic. Over time, termites had also caused serious damage to the main structural components, resulting in part of the house leaning to one side. We began by taking detailed measures on-site to understand the existing structural system and reinforced the areas that were most damaged. Some of the damaged columns were completely replaced, while others were partially cut and repaired at the base. We also preserved certain elements such as patterned wood ceilings to respect the history of the house. For instance, the glass in the study room’s door came from a window we unexpectedly found while demolishing one of the walls. It turned out to be a type of glass that’s no longer in production, so we reused it. Beyond that, we added insulation, designed custom furniture to fit the house, and carried out many small-scale adjustments. On a larger scale, we restructured the layout by connecting previously divided rooms, introducing a new rhythm to the interior flow. Since the home has a great view and is of a generous size, we thought it was important to emphasise a sense of openness through spatial expansion.

Kim Hyerin: I noticed that many of your recent projects, including PWD, maintain the original exterior while reconfiguring the interior layout.

Son Juhui: Reconfiguring the flow of an interior is often where we make our architectural interventions. Most people, when they move into a certain space, don’t necessarily think about how its layout will transform their daily lives. That’s where a designer’s touch becomes essential, especially when it comes to detailed planning of circulation and spatial flow.

Kim Hyerin: In that sense, is there a certain sense of responsibility you feel as architects?

Kim Dohyeong: We try to avoid architecture that feels indifferent. It’s not just about constructing a form. We think about how a design will actually impact someone’s life once it’s in use, ensuring architectural legitimacy.

Son Juhui: For most people, building a house involves investing their entire life savings. That’s why we can’t approach it lightly. Especially when it comes to houses, I believe that architects are responsible for it until the end. We try to follow up and make sure that the clients are living well in the house afterwards.

Kim Dohyeong and Son Juhui, our interviewees, want to be shared some stories from Son Minsun, Cho Hyeongjun (co-principals, artist duo Mu:p) in August 2025 issue.

Kim Dohyeong and Son Juhui