interview Kim Seung-il (director, STANDARD.a) x Park Semi

Standard A is a furniture studio that designs and produces wooden furniture, such as chairs, tables, and bookcases, under their design philosophy of ‘The Most Honest First Proposal’. One might wonder how the Standard A, a brand which will celebrate ten years this year following its predecessor, Indie House, is unique, whether it's in people, in design, or in the way they work.

Park: Nowadays, furniture studios adopt various forms of existence. They define themselves as designers, single studios, design studios, manufacturers, etc., depending on working method, scale, what they are aiming for or what they think. Which is the closest to the identity of Standard A?

Kim: To be honest, I think it is wordplay (laugh) It may be due to the difference between English and Korean. It feels as if you're only designing in a studio and producing in a studio. You can also design in the studio. Also, when it comes to business, it has a sharpened image for taking jobs from another company. If you really want to get into the pun, 'Showroom Seogyo-dong' is a studio, and 'Factory Jukjeon' is a workshop. Our current position is somewhere between the workshop and the factory. We maintain an environment (as a workshop) where individuals can work, but we are also introducing a factory working system to some extent.

Park: While continuing to design, it also takes a factory production method, which may have to do with ordering and production methods. Although there is information on projects and products on the Standard A website, it is not a system that allows for payments online. It is conducted through telephone, email, and store visits.

Kim: You can also take orders over the phone, but I recommend you visit the store. This is because we want customers to understand the characteristics of our wooden furniture before they purchase. One of the most common misconceptions is that expensive things will be perfect. Each work of solid wood furniture is not exactly the same as another; this is because not only the texture or condition of the trees is different but objects made from natural materials change over time. You need to understand the changing process, we go through a counselling process. It is a crucial to buy something with or without knowing.

Park: What are the specifics of the process from ordering to production and installation?

Kim: Customers come to the store to check the products they have seen online, and we explain the features and pros and cons of the product. We then discuss whether the product is suitable for the consumer – that is the most important aspect. We talk in detail about the lifestyle of the consumer, the space in which to place furniture, and the reason for using it. No matter how good things fit, it would be best if you didn't buy them. Of course, the criteria also include factors such as price and sustainability. If the contract is made after sufficient consultation, the production period is decided, and production starts. It goes through sketch drawing, wood selection and assembly, cutting and levelling, CNC machining, assembling, sanding, and finishing. It is our job to explain the phenomena that may occur in the future once installed, and to offer guidance concerning how best to deal with them.

Park: It seems that we can get a glimpse of the unique characteristics of Standard A, especially during the design consultation stage. Could there be a conflict between the design direction pursued by Standard A and the needs of your customers?

Kim: There are two ways you can purchase Standard A furniture. The original product can be seen at the store, and there is nothing to negotiate when it comes to the design other than the change in size. The custom-made pieces begin by listening to the reason for and background to the client’s furniture use because it needs to be redesigned. It's not as if the architect is talking to the owner, but we listen to things like the patterns of life at home from a minor taste and draw drafts. I don't think it's a matter of pride as a designer. We just work within the principles that we must follow. Just think of the meaning of the name Standard A. If there is a possibility that the table of the customer's desired design will wobble, we explain why and do not work that way. It's about keeping the basics of being durable as furniture. However, we believe that our design philosophy does not need to be reflected as long as it is custom made. And since it's something we do with our own hands, our style naturally reveals itself.

Park: What is the design for Standard A?

Kim: I think it's all implied in the word 'standard'. This also suggests that things be kept to a minimum. For example, the table must not wobble when eating. It is more standard that it should not be broken when you throw. We do not design even considering that part. Most people think of design as a form. The form is just one of the design elements. The design includes everything pretty or not, sturdy or not, expensive or not. The design we think, the standard, is not the form, but the basic level of expression. The core qualities of Standard A's design is not 'pretty' or 'looks good', but 'nothing strange'. Of course, when we make furniture, some items are designed beyond the basics, but we try not to cross that line as much as possible.

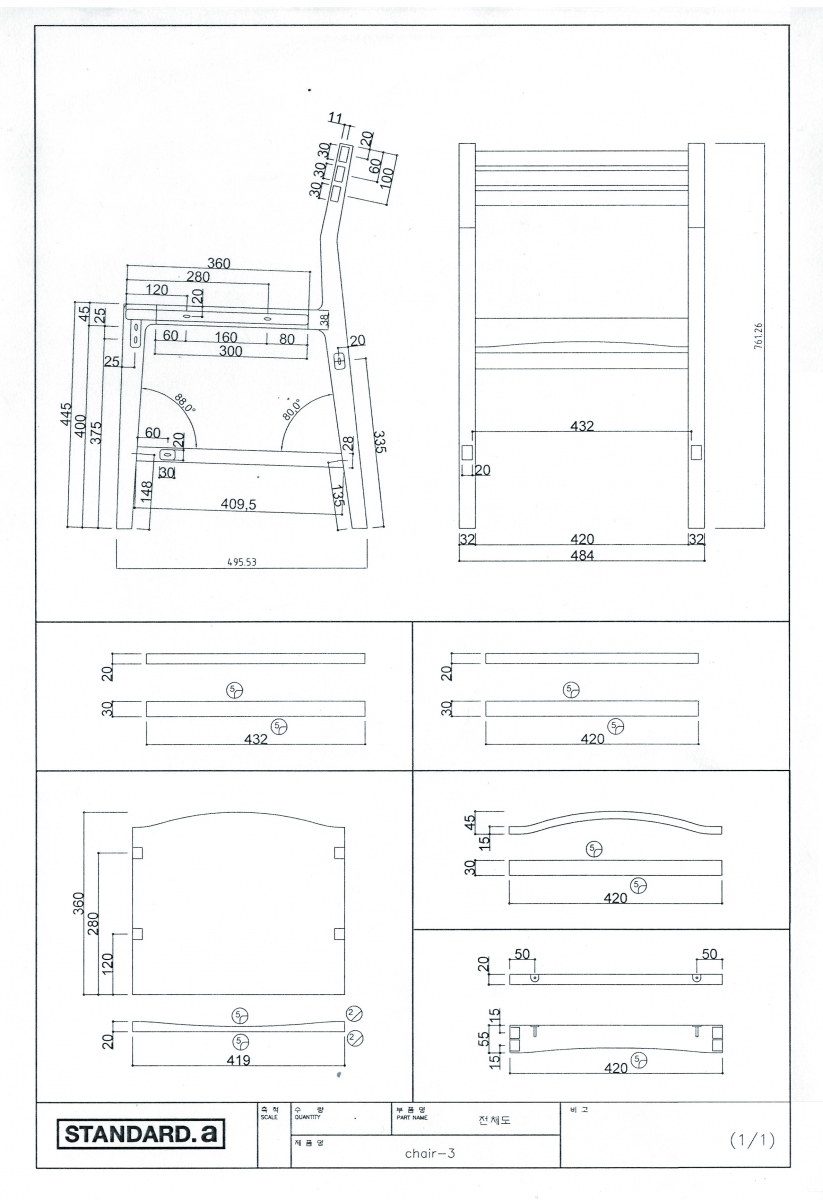

Product blueprint - Chair 03

Park: These days, it feels like the boundaries between furniture, interior design and architecture is blurring. Architects make furniture and furniture studios work on space. Even in the case of Standard A, are there any works that might create a unique atmosphere for a space through furniture…a project like Cafe Picnic or Wolhwa Inn, for example?

Kim: Speaking of the concept behind the Wolhwa Inn as arranged furniture, space itself cannot be established in the case of Cafe Picnic. Furniture is the interior design in Cafe Picnic. We participated in the planning and design phase. We continued to communicate with the architect of Cafe Picnic, Choi Jonghoon (Principal, NIA Architecture). First, Picnic planned to place 12 chandeliers, and we had to make something sturdy to support the quality of the light. As the chandelier is solid visually, I thought we should make a simple table, and I came up with the image of a gorgeous runway. I also had a lot of concerns about the table legs, and it was designed with the leg shape of the Trattoria chair by Jasper Morrison in mind, as chosen by the client.

Park: You said Standard A is in between a workshop and a factory. What is your opinion of handicraft and mass production?

Kim: Strictly speaking, all furniture must be handmade. There is no furniture made by the feet (laugh). Please let me know if you have a machine that makes furniture when you insert wood (laugh) Honestly, I don't want to praise the handmade. Based on the product concept, are all products 1 to 10 different from other products that have various defects? After all, the difference between the workshop and the factory is in the system. The system means a division of labour; elements of the factory work can be divided into cutting, assembling, sanding and finishing, and we have one responsible for cutting, assembling, and sanding. At least until assembly, one person takes charge of it. The finishing is for others. However, in the case of mass-produced factories, there are separate teams for those process. The cutting team is cutting wood all day long, not knowing what work of furniture they are crafting, and the assembly team just assembles the cut woods and parts. There is no room for the subjective thoughts of individual workers. However, if someone is responsible for multiple processes as we are, one can have a personal idea. It is the same type of furniture, but since the intention of the parts, such as where the wood grain meets or the positions of the knots, the expression of each piece of furniture is different. The factory is efficient, and the workshop is fun. Of course, in terms of sales and company operation, our system is ridiculous (laugh)

Park: Wasn't it chosen because you thought the system was meaningful?

Kim: I think it makes sense, but if we keep this system, the amount of things we can create is limited and the staff salary increases, so we have to raise our furniture prices eventually. Eventually, the time comes to move to the factory system. There are a lot of worries in the process.

Park: What is your plan? Are you planning to take on a different challenge than before?

Kim: I am considering how we might separate the original product from the custom-made. I want to go the way of the factory but also want to keep the studio form. It will inevitably become a factory, but I don't want to lose our soul (laugh) I want to do a lot of exciting projects while actively exposing the studio to the outside. The self-published magazines 'Log' or 'Hobby Life Project', which seem to be useless, are among those. I want the studio became fancy. I want to work in style.

kafe piknic. STANDARD.a made a table 18m long.

Sambakhanzip. Made large bed heads, dinning tables and chairs.

56