SPACE April 2024 (No. 677)

Modules are basic dimensions for construction. The number of modules varies depending on conditions such as the weight of the material, production method, movement and lifting of materials, and structural limitations. Ready-made materials made through production lines usually have specific dimensions that determine sizes for division. There is a limit to the length or area of jointless façades, or materials for casting and welding. The issues associated with division and connections are always present in architectural design. Modules are important elements in dealing with such issues.

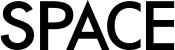

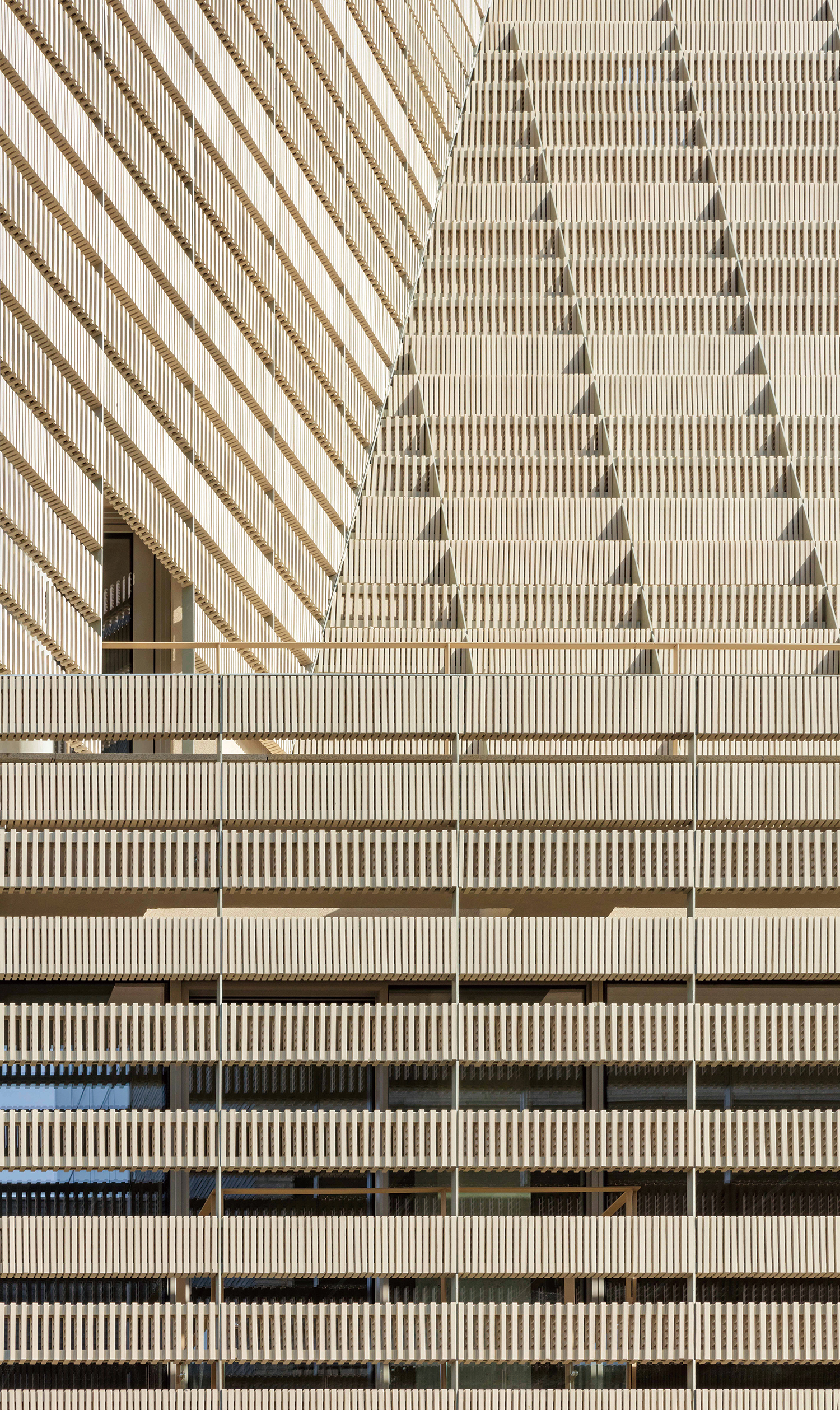

Fa-brick, a neighbourhood living facility located in Sinsa-dong, is a project that explores the potential of bricks – the smallest architectural module used by mankind for the longest time – as new decorative material. Instead of the wet stacking method using mortar, Fa-brick uses frames and fixing devices to attach bricks to the structure. The bricks are not stacked on top of the other, but are hung apart from each other. Due to this, the bricks function as a screen transmitting light rather than an opaque wall that severs the connection between insides and outsides.

(오른쪽) ©texture on texture

Dimensions of Division

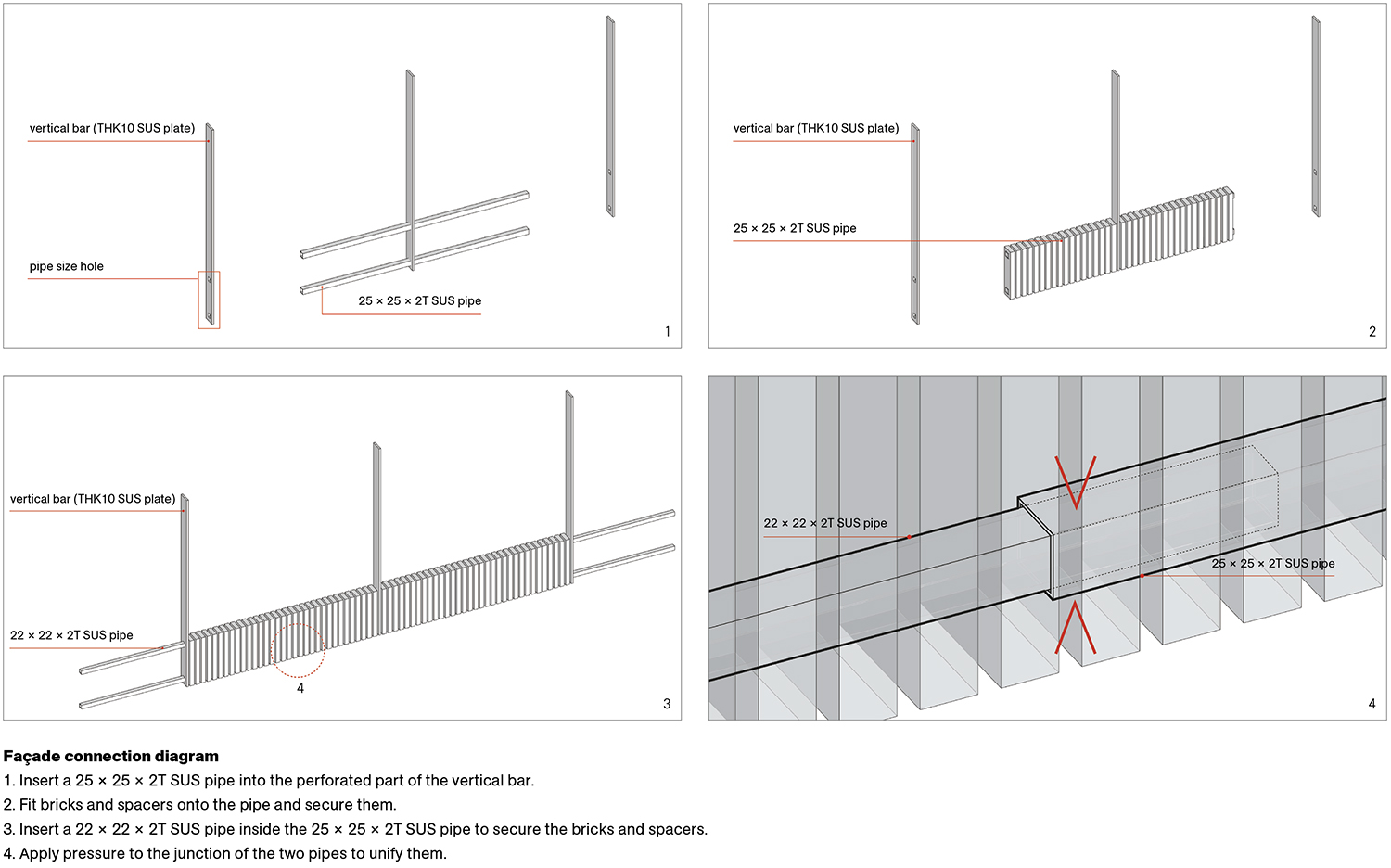

As basic units, thin bricks surround the entire building. For this purpose, it was necessary to calculate the common dimensions resulting from the combination of bricks (25mm) and spacers (10mm) for each façade dimension. A minimum module of 430mm was selected by calculating the least common multiple of 35mm (the sum of one spacer and one brick) and 55mm (the sum of three spacers and one brick). The reason for the two different modules when deriving the least common multiple was to create a difference in the spacing of the bricks. When there is a larger gap, there is an increase in both the amount of light shining through and the sight exchanges between inside and outside of the building. By appropriately arranging the two different dimensions, the project sought to achieve diversity of density in its façade. In addition, the hardware that connects the bricks and the vertical structural bar modules that connect the hardware to the reinforced concrete exterior wall divide the façade vertically at intervals of 1,210mm.

The basic unit of a 25mm-thick brick, is made by cutting lengths of 77mm-thick Spanish clinker bricks twice. Considering the thickness loss from cutting blades, the thickness of each brick is calculated as 25mm, with approximately ±1mm of error, resulting with brick thicknesses within the range of 24 – 26mm. The 1mm errors can easily be dismissed in architectural design, however in construction, the accumulation of these errors within a 1,210mm structural module may ultimately result in a gap exceeding 1cm. This can also be overcome by the condition that the bricks and spacers are hung without adhesion.

Making vs. Constructing

The bricks have square holes of approximately 31mm in order to reduce the weight and to increase strength by allowing mortar to penetrate between the bricks during construction. The façade of Fa-brick was constructed by sequentially threading the bricks through these holes. Ready-made zinc coated 30 × 30mm square pipes were used to thread the bricks. The construction processes are as follows. The bricks are first set in a row on a workbench; 1,210mm long square pipes are then inserted into the holes of the bricks. The bricks threaded by the square pipes are then lifted and fixed onto the base frame (stainless steel flat bar). The final step is to offset each brick and insert one or three ㄷ-shaped spacers in between each brick.

Spacers are made by pouring polypropylene into a mold. Its cross section is designed to fit into a 30mm square pipe with a ‘click’. Spacers are not intended to receive loads or form a bond between bricks, but simply to maintain a uniform spacing between bricks. The series of operations do not require the skill set of an experienced masonry worker.

Designed Details

When standing bricks are placed horizontally, the bricks meet at an angle of 90 degrees or 40 degrees or another angle at the edge of the façade. Strictly speaking, it is not the bricks, but the structural frameworks on which the bricks are hung that are meeting at these angles. An L-shaped gap created by stainless steel bars appears at the corner of the building. Bricks cannot be attached at this angle. Unlike Europe and Japan, where brick decorations are advanced and a variety of materials such as tiles are manufactured and therefore corner bricks and tiles are manufactured as special products, it is difficult to find such products in Korea. Granites are used as an alternative to these items. The corners are decorated and finished with 25mm-thick L-shaped units made from granites with the most similar colour and texture to brick. These function in a somewhat similar way to moldings.

In the case of the slope of the upper floors, shaped to cope with diagonal sunlight restrictions, the structural foundation frames are installed in accordance with the slope angle while bricks were mounted vertically. This results in horizontal arrangements following the same principle as a generic façade, while vertical arrangements are finished in a stair shape. The inclined structural frames are exposed at an acute angle between the bricks, clearly revealing the bonding relationship of bricks and metal.

As a result, the building takes on the shape of horizontal bands of vertical brick lengths. The upper and lower spacing of the bands varies across options of 50, 100, 150, and 200mm. The spacing between bricks at human eye level is sparse, while those between bricks in the slab section are dense to adjust the visual sense of openness as needed. For example, at eye level the brick bands were placed with 150 to 200mm spaces, and at slab areas the brick bands were placed with only 50 to 100mm spaces in between. The different vertical and horizontal spaces within the modules adjust light transmittance in various ways. Additionally, this restricts the view from the outside, ensuring privacy in a dense residential area.

Bricks: Varied Craft

Bricks are very small materials, but when tens of thousands of bricks are gathered together, they form surfaces and volumes. By adjusting the distance between bricks and changing the various relationships with the metal frameworks, different impressions are created due to the variation of sunlight passing through, while surface textures from afar also vary. Although the area is blocked, there exists a variety of visual and perceptual effects created by small differences, similar to that of light and wind passing through fibre structures of varying sizes. As the name of the building suggests, it is the effect of ‘fabric’, which is woven into warp and weft threads.

Surrounding the project are numerous brick buildings commonly found in the Class Ⅱ general residential area of our city. Within it, Fa-brick wears the same clothes, yet exists in a slightly different texture. New possibilities were sought of a material that was long used by mankind, by utilising a different construction method. The difference in construction methods lies in the handcraft nature of handling the materials. Fa-brick is the result of rejecting the technology that can mass produce a wide variety of complex, 3D curved surfaces or print an entire building at speed, and instead considering architectural craftmanship somewhere in between making and constructing.

Kang Yerin (Seoul National University) + SoA (Lee

Lee Jeongyeon, Cho Jaemin, Rim Haeun

40-5, Nonhyeon-ro 159-gil, Gangnam-gu, Seoul, Kor

neighbourhood living facility (office, retail)

200.2m²

119.99m²

466.11m²

B1, 4F

3

19m

59.94%

196.87%

RC

brick, Low-E glass, exposed concrete, EIFS (exter

exposed concrete

Base Structural Consultants

Jusung ENG

Chung Song Engineering & Construction

Kiro Construction

July 2020 – Jan. 2021

Sep. 2021 – Apr. 2023